How do you reduce risk and facility downtime while increasing operator efficiency and emergency preparedness? Imagine 4D and partners have had the opportunity to assist nuclear power plant operators in meeting this ambitious challenge by creating a Digital Twin. The first phase of this project is slated for delivery by the end of 2020.

This case study covers:

- What is a Digital Twin?

- The Nuclear Power Industry

- Digital Twins: Increasing Operator Efficiency

- Station IX™: A Digital Twin Creation, Integration and Interaction Platform

- Project Scope

- Project Highlights

- Project Toolset: Workflows for Digital Content Creation and Model Integration

- Overview of Imagine 4D

What is a Digital Twin?

Digital Twins are animated models of real-world assets and can be used to emulate or simulate the physical world.

They can be used to replicate equipment, facilities, and processes and allows businesses to make better informed decisions and improve solution life-cycle efficiency by reducing time and cost related to design, operations, and maintenance while improving asset maintenance.

Digital Twins generally are constructed by creating enhanced visual representations of physical assets in the form of 3D models that are then integrated in a synthetic environment. Digital Twins are animated by injecting sensor data and/or simulation outputs to duplicate or generate the desired behaviors.

The use of Digital Twins is part of a preventive or proactive solution life-cycle approach since the insights gained from interacting with the Digital Twin or from analyzing the results of Digital Twin simulations allow organizations to detect and avoid problems before they happen. They can also reduce facility downtime, contribute to improving situational awareness required for decision-making during operations, provide the basis for operator training, and allow for product testing in a virtual environment before actual launching.

To learn more, please refer to our Digital Twins page.

The Nuclear Power Industry

Providing roughly 10% of the world’s total electricity, nuclear energy is used for powering our homes, for space exploration, for research, and for many other purposes. Keeping nuclear power plants running smoothly and safely is of paramount importance.

In spring 2019, Imagine 4D and its partners embarked on a Digital Twin project for a nuclear power plant that entailed creating a full 3D replica of newly commissioned nuclear reactors based on a composite 3D model generated from CAD drawings and point clouds generated from laser scans. This 3D model forms the basis for an operator training capability that will ensure smooth, efficient and safe operations as well as improved plant familiarization and emergency preparedness.

Digital Twins: Increasing Operator Efficiency

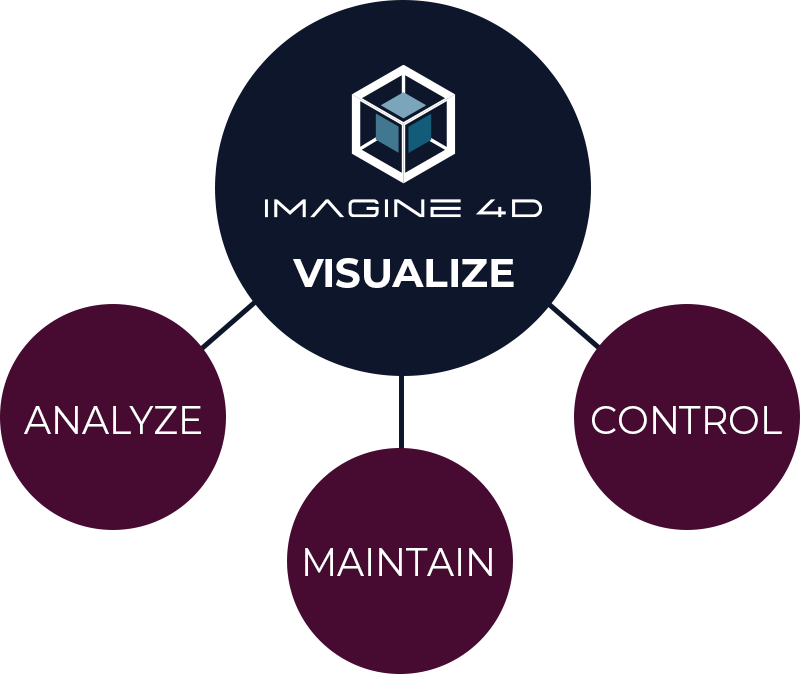

There are 4 main operational functions that can associated with the use of Digital Twins: Visualize, Analyze, Maintain and Control. Imagine 4D has mastered 3D visualization and their vision is consistent with the belief that the better the operator can perform the visualization function, the easier it is to perform the subsequent analysis, maintenance, and control functions. For this project, Imagine 4D’s goal was to create a full 3D model and virtual companion of the customer’s nuclear reactors. Our scans and models would enable, among other things, improved project planning and training solutions, as well as improve time management and safety during plant walkthroughs.

8 planned benefits for this project:

Design Support

- Detect design errors

- Generate an accurate as-built representation

- Provide platform for design modifications

Operational Effectiveness

- Improve training

- Improve work planning and task briefings

- Increase effectiveness of plant familiarization

- Reduce time for plant walk downs & locating equipment, determining most efficient travel paths & reducing dose exposure

- Improve understanding of equipment line-ups to support maintenance activities

Station IX™: A Digital Twin Creation, Integration and Interaction Platform

Imagine 4D brings a value-added digital content creation and integration platform and toolset to the project: Station IX™: The Multimmersive Experience™. Driven by our proprietary technology, Multimmersion™, Station IX™ is a collaborative and interactive display system that allows groups of users to view 3D content at a glance in a headset-free environment. This unique visualization technology provides the ultimate viewing experience to work with high-value 3D data, in a variety of forms such as Digital Twins.

Project Scope

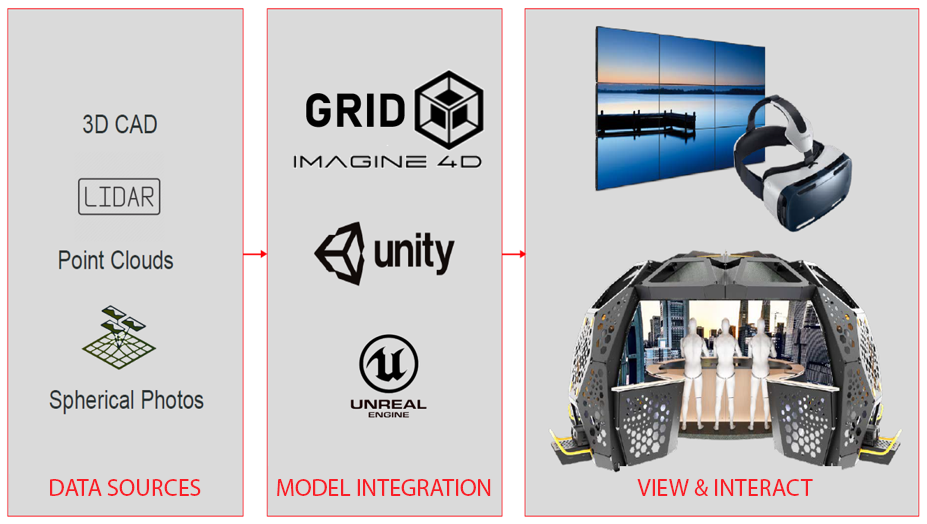

Together, Imagine 4D and its partners, are providing 3D point clouds and other highly accurate, and realistic 3D models generated from 3D laser scans, engineering drawings, and other data sources using Imagine 4D’s proprietary disruptive digital content creation and visualization technologies. The solution is designed to deliver the end result in a well-organized format that is easy to use and modify, and that supports multiple interactive visualization modes.

The end user can interact with detailed models using conventional computer displays, VR headsets, or using Imagine 4D’s Station IX™ Multimmersive™ environment and digital content integration platform equipped with Imagine 4D’s patented Multimmersion™ display technology.

One of the main project goals was to ensure that the client could offer a train-as-you-operate capability to their employees without impacting actual plant operations. This was accomplished by providing access to a representative simulation with realistic virtual equipment. To achieve this goal, the solution integrates plug-and-play 3D models that are supported by multiple game-engines and are simulation-agnostic. The digital content creation pipeline allows for seamlessly creating, updating, and implementing 3D models and this translates into less time spent on preparing models and more spent training.

With over 20,000 laser scans and a multiplicity of moving parts, the model is more than three times more complex than any AAA game on the market today. This made the project execution more complex and required putting into place an extensive asset management and content creation architecture. In the end, Imagine 4D and partners were up to the task.

Project Highlights

- Level of complexity is 3X greater than any AAA game on market today ($50M-$70M+)

- Extensive scan of large nuclear power unit was scanned including: containment, auxiliary, T/G and common services buildings

- Data acquisition included over 10,000 spherical photos and over 10,000 point clouds

- Engineering source data set includes over 4,000 3D CAD files to date, more files to be ingested

- Nuclear Power Plant Model includes 85,000 individual components: equipment, instruments, valves, dampers

- All engineering data will be preserved (every component retains its original attributes/metadata)

Project Toolset: Workflows for Digital Content Creation and Model Integration

Our project team created a wide variety of tools to support the end-user. These tools included a workflow engine to generate, update, integrate, and interact with the Digital Twin. Examples of the toolset functions include avatar customization, measurement and inspection tools, scenario building for operations, emergency preparedness, and maintenance. Imagine 4D provided the client with a virtual environment that links the customer’s data to 3D assets at the component level with full traceability.

The toolset supported the two principal modelling activities: in situ scans and the 3D model creation, performed by separate, dedicated teams with required training. Imagine 4D’s used their expertise in both these aspects of the project combined with expertise in providing multiple interactive visualization modes in the Station IX™ headset-free Multimmersive™ environment. Imagine 4D and its partners make it simple for clients to create precisely what they are looking for, with the highest quality possible, all in one place.

Overview of Imagine 4D

Imagine 4D is a Montreal-based technology company. Immersive 3D visualization solutions drive our passion and we believe the use of 3D content is growing and brings a multitude of opportunities for businesses. Our team of experts designs technologies that foster collaboration, build trust and accelerate decision-making in the workplace. With our cutting-edge expertise in immersion and our proprietary headset-free 3D environment, Station IX™, we dare to challenge the status quo by introducing technological breakthroughs that will help businesses achieve their objectives and minimize risks.

By choosing our team, the client invested in quality and flexibility. Keeping speed and value in mind, our team adopts a standardized approach in developing visual solutions that ensure compatibility across multiple game engines. Recognized for an agile delivery and unique problem-solving approach, we can also produce some of the most hyper-realistic and immersive 3D visual content in the industry.